The marine industry has long prided itself on its craftsmanship and skill acquired through years of practice. However, even with the most skilled hands doing the work, it’s a common occurrence that decks and hulls do not fit together due to the mismatch between design and realities of how parts come off of the mold. Until recently, the only way to account for this was to grant larger-than-ideal tolerances, resulting in a lack of dimensional control. An effective solution to this has been elusive using traditional measurement methods however, by utilizing laser scanning and 3D measurement we have been able to offer our clients the information they need to avoid costly mistakes, improve their efficiency and quality and take the guesswork out of their production.

With our team’s years of 3D scanning experience, we can quickly identify issues that impact the lamination and construction processes of many types of watercraft — no more cutting and modifying until everything fits. Whether we’re scanning freshly made parts, or being involved in your mold or plug redesign, we can supply your engineering team with information that is imperative, such as understanding deformation, or draft compensation for shrink just to name a few. Our goal is to reduce time spent revising your parts, which increases efficiency and product quality.

For workboats, pleasure boats, and any type of watercraft, 3D scanning services from Diverse Dimensions are invaluable, saving time, money, materials, and headaches from pre-production through final assembly.

Boating & Marine Metrology Services

We work with naval architects, boat designers, mechanical engineers and product developers on all types of watercraft.

3D Laser Scanning for Watercraft

Working alongside master plug builders, lamination experts, and naval architects, our team of metrologists are highly skilled at scanning and accurately capturing dimensional data that can assist with quantifying your designs before you finalize your production mold.

Fiberglass Plug & Mold Inspection

During pre-production, our scanning and inspection services ensure that a plug is accurately cut per CAD so that it will translate into your mold and finished parts.

Being involved early on in the process allows our team to provide a data feedback loop before you go into the production of hulls, decks, and liners.

Once a mold has gone into production, we can periodically check it to give an idea about remaining mold life.

Reverse Engineering Components & Design

Reverse engineering can do any number of things while working with existing molds. You might need to reproduce lost or nonexistent CAD data, even from a mold that has deteriorated, or troubleshoot a part or mold to find the root cause of an issue during lay up, or keep good data and records on your (and your competitors’) products.

With 3D scanning for reverse engineering, you can solve problems that exist, prevent problems that might eventually exist, and save time and money on materials by increasing efficiency.

Benchmarking products from competitors is important in all industries to understand where you are in relation to the competition, and particularly so in the marine and boating industry. We help benchmark and compare your products so you have all the information you need.

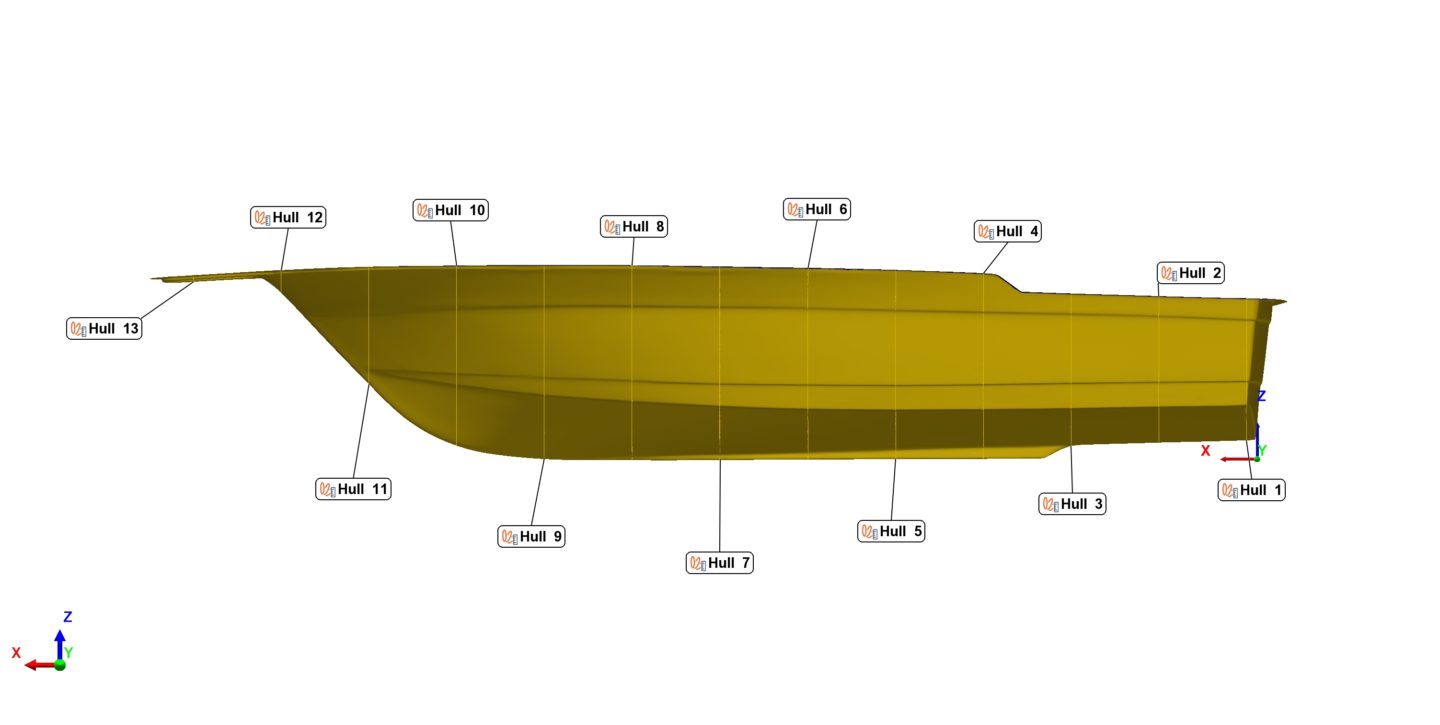

Reverse engineering hulls provide valuable information to aid with buoyancy testing and Computation Fluid Dynamics (CFD) modeling and analysis. When Viking Yachts wanted to change out the placement of its primary drive engines, we reverse engineered the hull to figure out how changes to the drive design would affect buoyancy and stability. When a Coast Guard regulation on workboats related to a weight change of more than 2% on boats over 26 feet required re-certifications, CFD was part of the process.

We can also reverse engineer fiberglass patterns using a Faro arm or laser tracker resulting in a cut file to be used with a CNC cutter rather than hand cutting. Boat manufacturers who digitize their designs and move away from hand cutting reduce material waste, standardize cut plans, and reduce labor costs substantially.

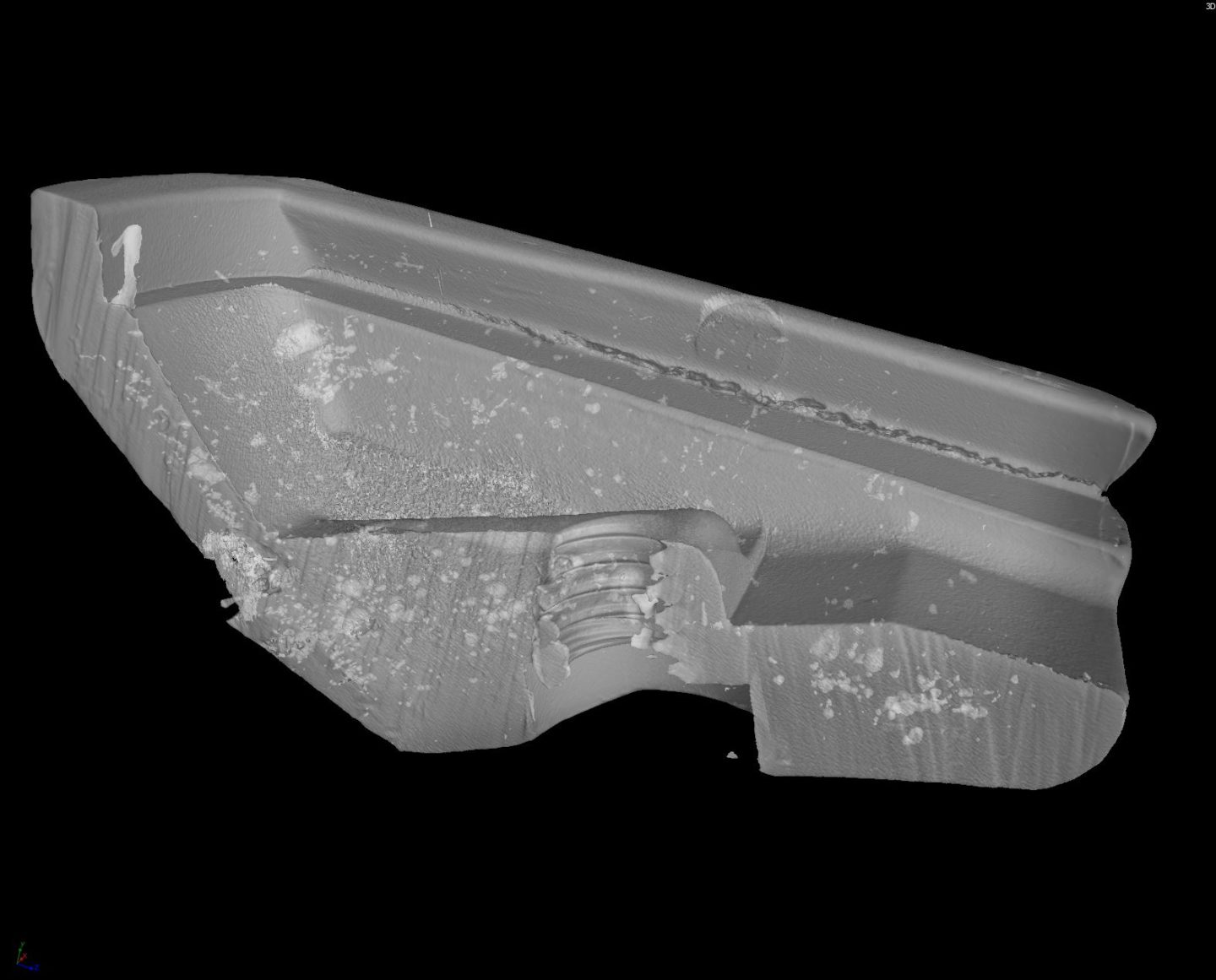

Non-Destructive Testing & Evaluation for Watercraft

Non-destructive testing (NDT) and non-destructive evaluation (NDE) are ideal for the boating and marine industries given the critical nature of many of the components as well as the environmental conditions they’re subject to. CT scanning provides valuable data on how components fit together, root causing field failures and inspecting build quality – check the number of layers in a layup.