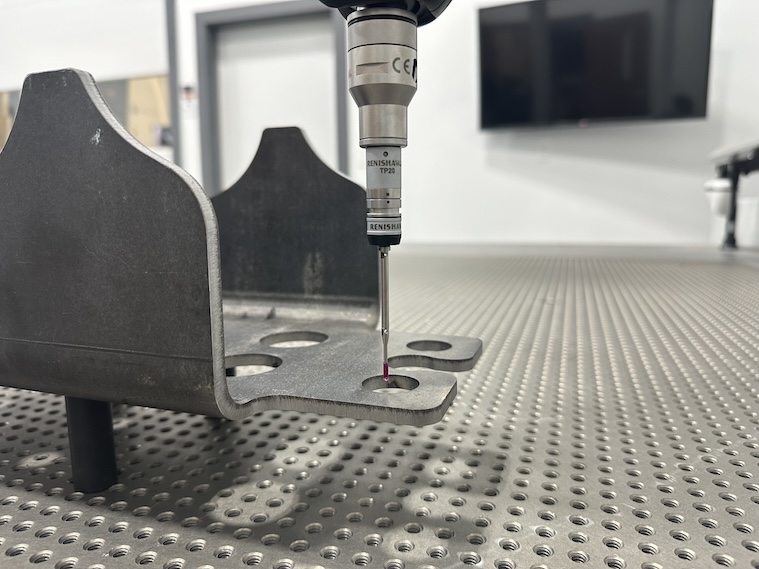

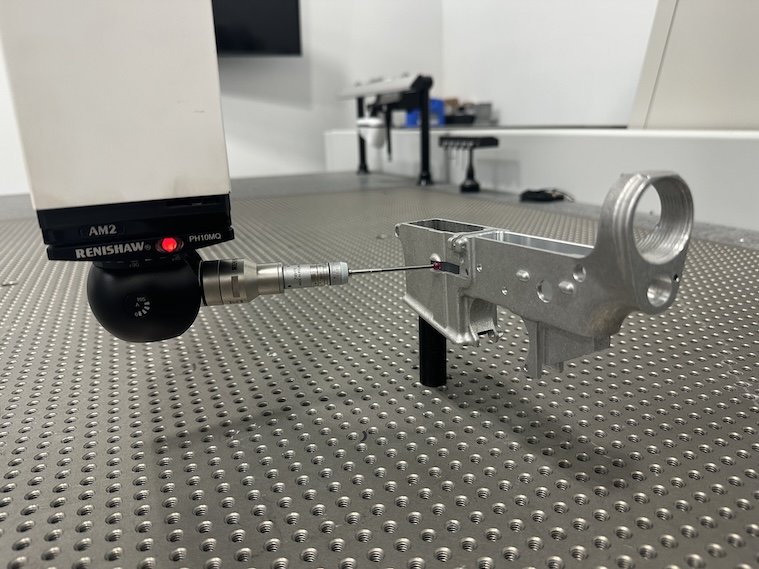

CMMs are time-tested and trusted to deliver highly accurate data time after time. From 30-piece studies to one-off parts, the CMM will tell you exactly what’s going on.

Large Volume. High Accuracy

CMM inspection delivers microns of accuracy, ensuring reliable measurements in every project. Expect swift service with turnaround times typically within 1-3 business days.

- ISO 17025 Certified

- Measurement Volume: 100″ x 60″ x 50″

- PPAP

- First Article Inspections (FAI)

- Fixture Certifications

- Dimensional Analysis & Inspection

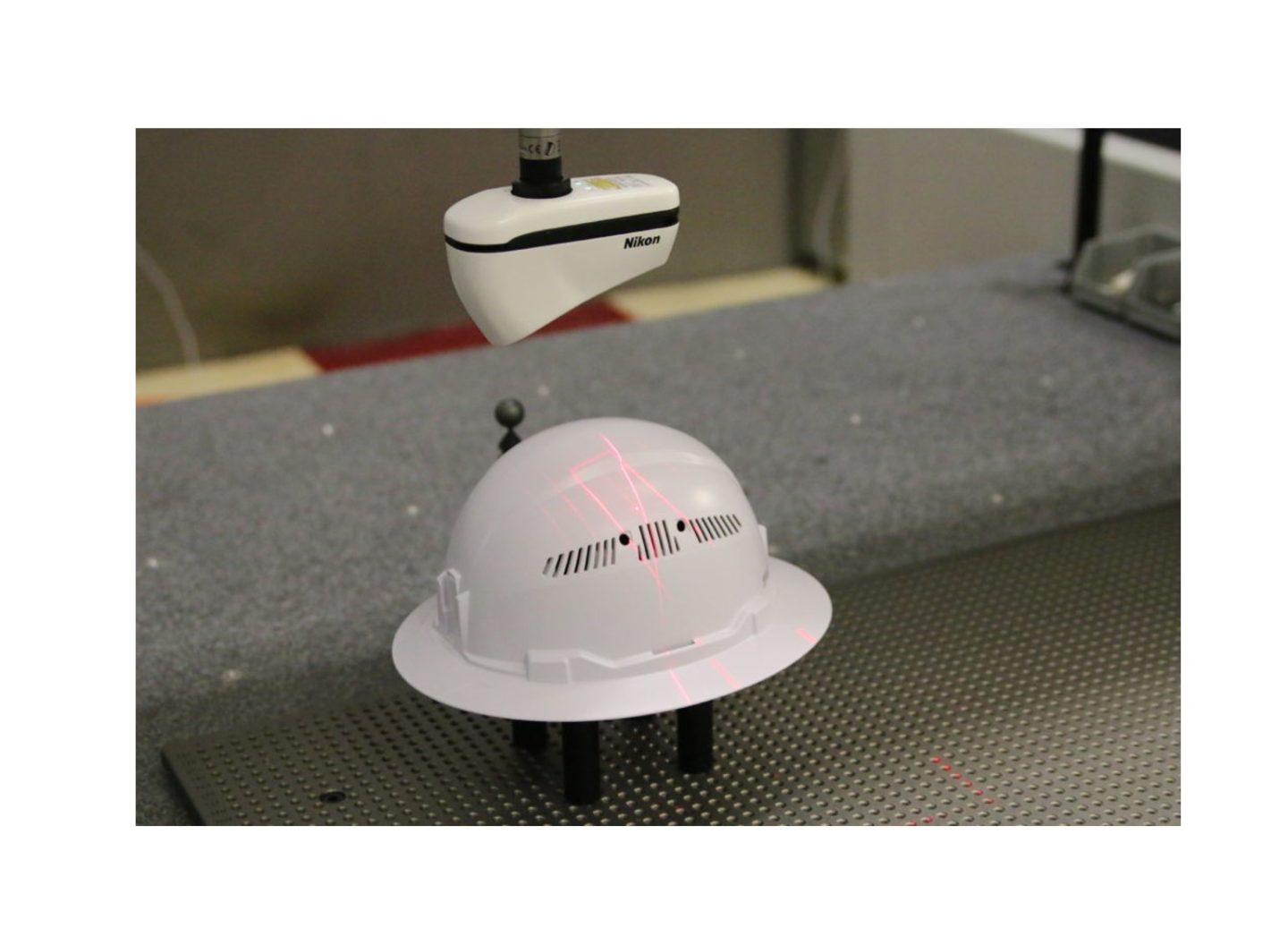

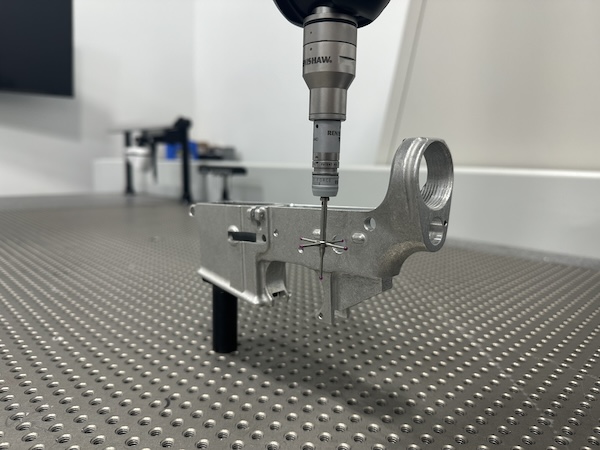

Laser Scanning

Backed by a CMM

Combine the best of all worlds with CMM probing and scanning. By selecting the optimal angle for each scan pass, we can deliver the highest quality scan data. Scanning can also speed up the measurement process for large-quantity runs.

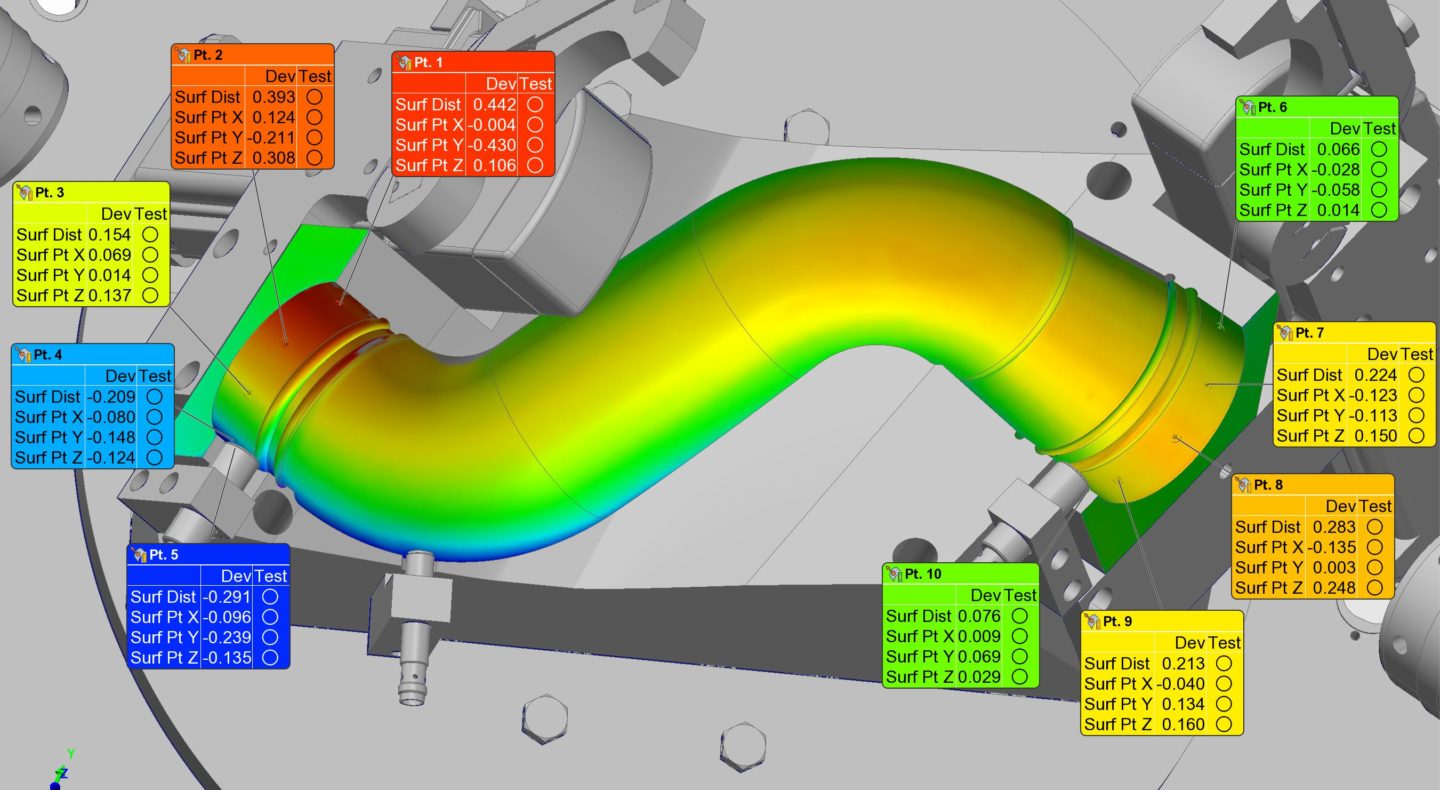

Visual Reporting

No more spreadsheets! We’re running Polyworks on our CMM, allowing us the ability to generate highly visual, pictorial reports which are easy to understand.

- Geometric Dimensioning and Tolerance Analysis (GD&T)

- 3D Color Maps

- 2D Section Analysis

- Comparative Analysis

- Statistical Process Control Charts (SPC)

CMM Applications

-

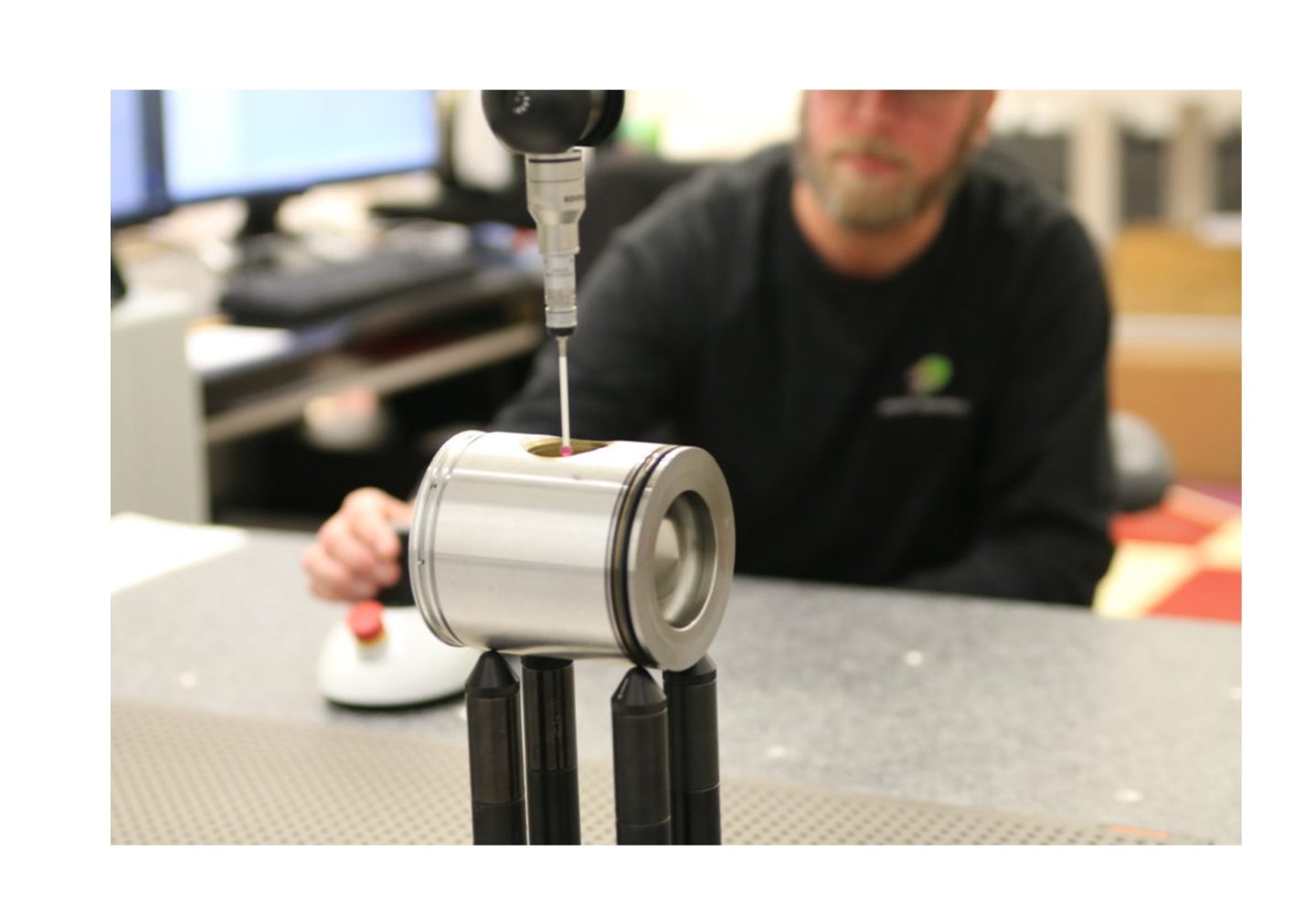

Dimensional Analysis & Inspection

Identify nonconformities that affect part, item, or assembly performance. Manufacturers trust our CMM team to scan their parts for geometric tolerance verification and profile analysis. Leveraging a robust software suite and highly accurate metrology equipment, we generate detailed inspection reports without causing damage or altering the integrity of your components.

-

First Article Inspection (FAI)

Ensure conformance with design specifications with this crucial quality assurance step in your manufacturing process. Our skilled team of CMM technicians thoroughly measure, verify, and document components for compliance assurance throughout the FAI process.

-

Capability Studies

Measure process capability (SPC, CPK) and identify areas of improvement in your manufacturing process. Critical to process and manufacturing improvement, CMM allows our team to capture and analyze data at scale, delivering you with the information necessary to make decisions that impact your bottom line.

-

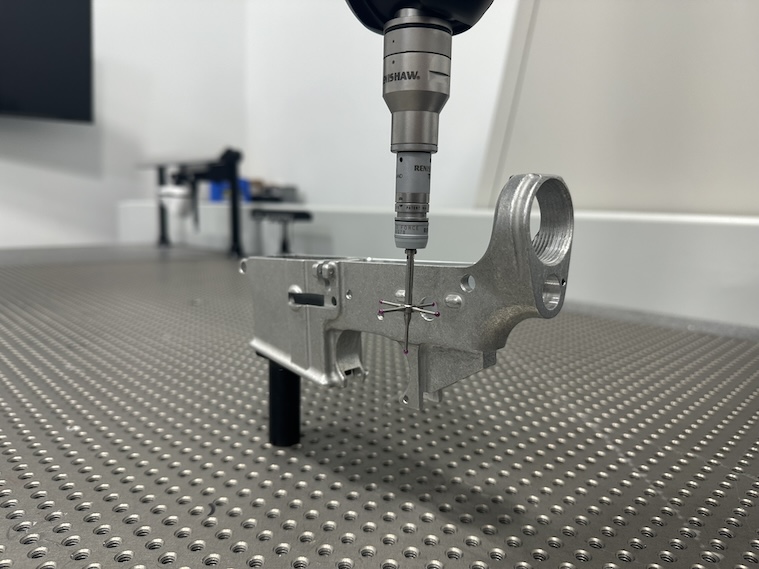

Part to CAD Comparison

Compare 3-dimensional scan data to a CAD model and repeat the process at scale. Essential for quality control, inspection, and ensuring the manufactured parts conform to the intended design to further validate your manufacturing systems.

-

Production Part Approval (PPAP)

The Production Part Approval Process (PPAP) is an industry-standard, and it's something we do quite well. We start with a thorough measurement and inspection of your part, verify dimensionally, and ensure geometric and surface finish tolerances are in specification.

-

Microns of Accuracy

Our CMM process is continuously monitored and maintained to deliver manufacturers with an elevated confidence level, knowing that when we scan a component, it is a highly accurate report that can be replicated time and time again.