Experts in Root Cause Analysis

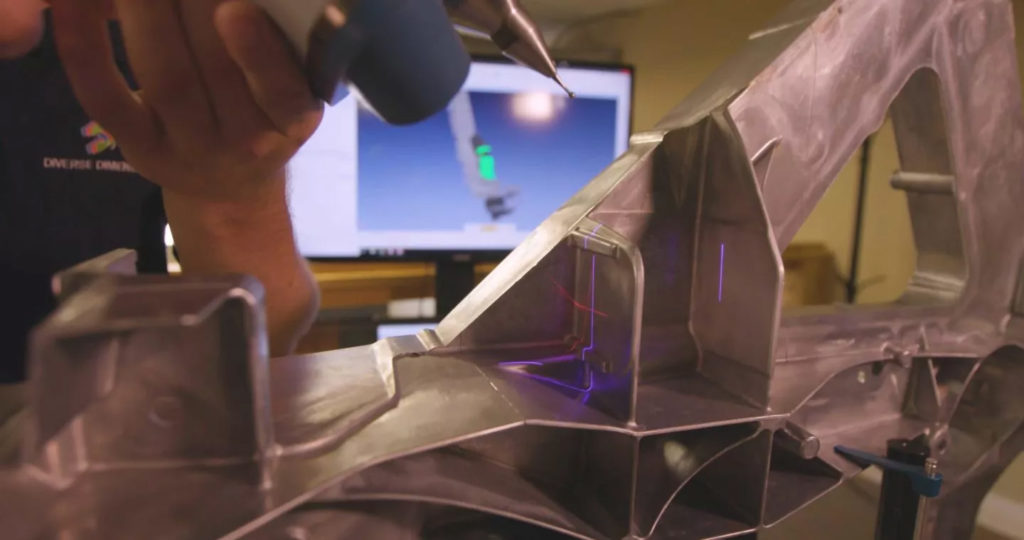

Our full-service metrology lab supports a wide range of industries with precise dimensional inspection services. With experience in government contracts, marine applications, and more, we're equipped to take on complex projects. As experts in root cause analysis, our team takes a systematic approach to identify the underlying issues and drive process improvements. No matter the industry or project, our team delivers accurate insights and results.

Key Industries

Boating & Marine Industry

From 3D laser scanning to fiberglass plug and mold inspection, our team brings valuable knowledge and experience to the boating and marine industry. Partnering with Diverse Dimensions early in your project allows us to identify issues before production, saving time and reducing costs. While the boating industry is known for its craftsmanship, 3D scanning and reverse engineering take precision and craftsmanship to the next level.

Government Contract Work

Our trusted metrology lab has provided metrology solutions to government entities for over 20 years. We’re ISO 17025-accredited and CMMC compliant, with a clear understanding of the demands of projects. From First Article Inspection (FAI) to Production Part Approval (PPA), we’re ready to support your requirements. Explore our core competencies and NAISC codes to see how we align with your needs.

Additional Industries We Serve

We serve a wide range of industries beyond government and boating & marine, including medical manufacturing and automotive. Don’t see your industry listed? Contact our team today to find out if our services are the right fit for your project. We’re here to be your trusted partner for metrology projects of any kind.

- Medical Manufacturing

- Automotive

- Aerospace

- Furniture Manufacturing

Explore a Solution for Your Project

From CT scanning to CMM inspection and programming, we offer a comprehensive suite of metrology solutions. Explore our full-service metrology lab to find the right solution for your unique project.