Modern Measurement Solutions for Boating & Marine

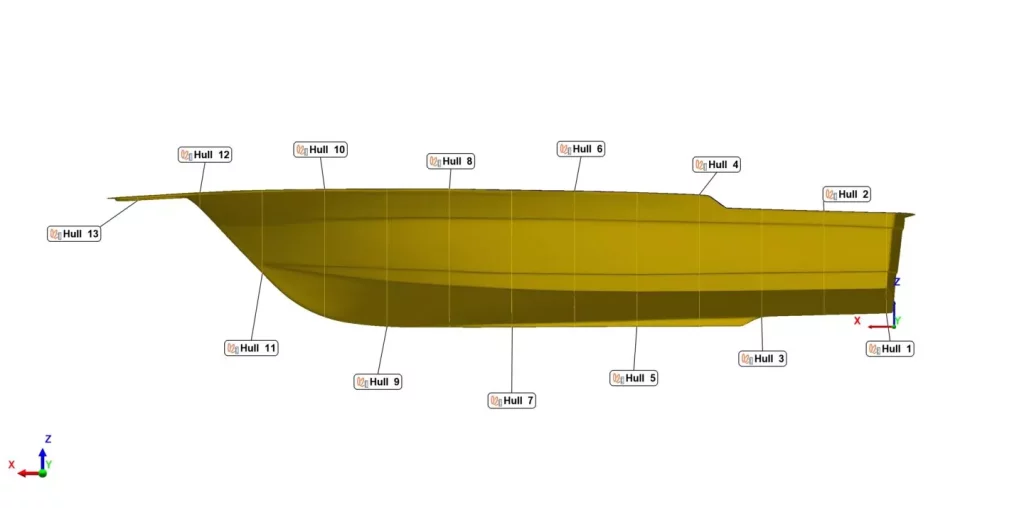

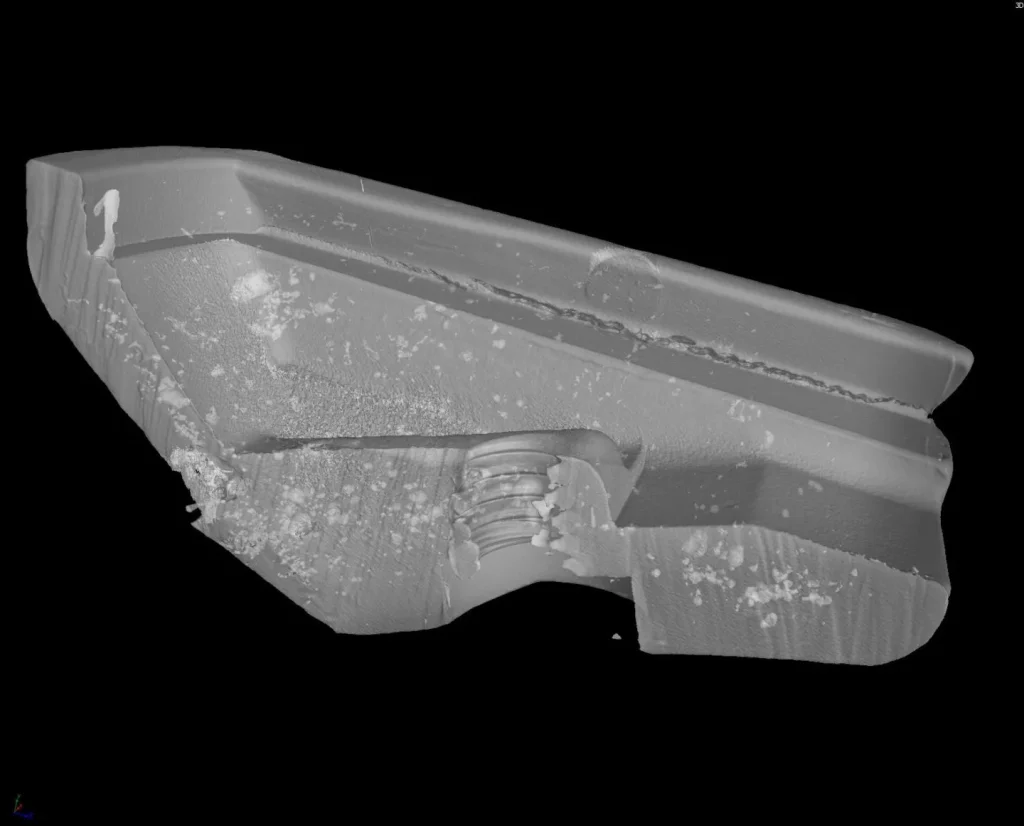

The marine industry has long prided itself on its craftsmanship and skill acquired through years of practice. However, even with the most skilled hands doing the work, it’s a common occurrence that decks and hulls do not fit together due to the mismatch between design and realities of how parts come off of the mold. Until recently, the only way to account for this was to grant larger-than-ideal tolerances, resulting in a lack of dimensional control. An effective solution to this has been elusive using traditional measurement methods however, by utilizing laser scanning and 3D measurement we have been able to offer our clients the information they need to avoid costly mistakes, improve their efficiency and quality and take the guesswork out of their production.

Watercrafts We Service

For workboats, pleasure boats, and any type of watercraft, 3D scanning services from Diverse Dimensions are invaluable, saving time, money, materials, and headaches from pre-production through final assembly.

- Recreational Boats

- Commercial Boats

Don’t see your type of watercraft listed? Contact our team today to determine if our services are the right fit for your project.

Our Expertise in the

Boating & Marine Industry

Contact Us for Boating & Marine Metrology Needs

We’re committed to saving you time and money, and making product or production improvements through our expert metrology solutions. Boat manufacturing is a complex industry that requires high attention to detail and precision. No matter your type of watercraft, we’ll work with you to find a solution to your project. Contact us today for your boating and marine metrology needs.

Explore Our Full-Service Metrology Lab

Our full-service metrology lab is equipped to provide accurate and reliable solutions for your metrology needs. With a team of metrology experts, we offer quality analysis, measurement, reverse engineering, laser tracking, training, and consulting.