Using Industrial CT Scanning to Determine Material Thickness & Gap Width

Knowing where a part’s potential weaknesses lie can be a huge cost and time savings, especially if you’re working with high volume part runs. By using industrial CT scanning, we can identify areas that are prone to weakness, or where the wall thickness has reached undesired values.

A single scan can determine a component’s material thickness and gap width with highly accurate measurements (+/-.010mm). We can measure, observe and inspect the internal and external components of an object in 3D space, and specifically measure various parameters within those surfaces. The main advantage of CT scanning is being able to inspect the inside of a part or object without causing any harm or destruction to the objects themselves, also known as nondestructive product testing (NDT).

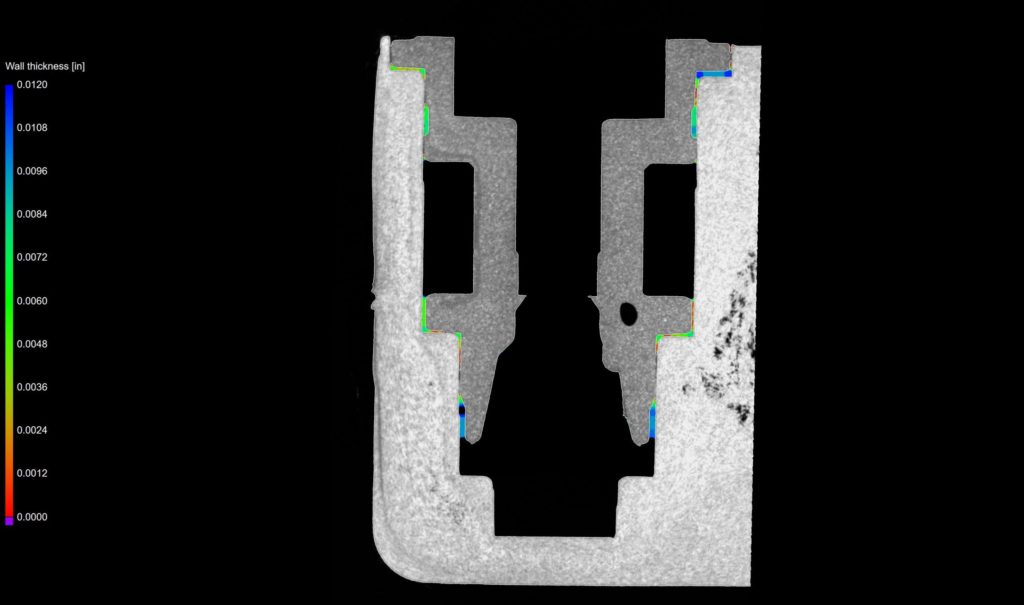

Wall Thickness Analysis

Oftentimes, industrial components must be kept within a certain tolerance. An industrial CT scanner will create a boundary around all components within the part, both internally and externally. The distance between every single surface is then calculated and specified as the minimum wall thickness. The results are represented in a color coded model that shows variations from a previously specified wall thickness. In addition to the 3D color coded model, the scanner also creates a 2-dimensional cross sectional whisker plot to show wall thickness deviations in cross sectional slices.

We can also apply tolerances to the wall thickness analysis with specific parameters such as the minimum, maximum, mean, or deviation. Variations from the previously determined wall thickness can be sorted by a range.

Benefits

- The color coded representation identifies the areas that are prone to weakness, or where the thickness has reached undesired values.

- Finding variations in the wall thickness can eliminate errors that would have been costly to the manufacturer.

- The scan can identify walls that are too thin for structural or pressure requirements

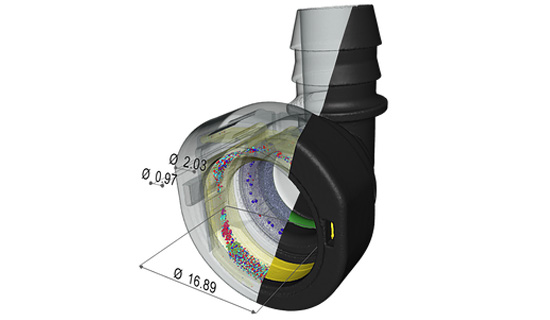

Image via RX Solutions – a highly innovative Industrial CT Scanner Manufacturer

Starting with an actual object or prototype, we can use the CT scanner to take precise measurements of the existing part and create an exact CAD replica in point cloud format. The CAD file is useful because if any future issues arise, we can accurately review the component digitally. Using the latest laser scanning and reverse engineering technology, we deliver exactly what you need with speed and precision.

Comparing CAD Nominal Data and CT Scanned Data

Through industrial CT scanning, a comparison can quickly be made between a scanned component and the CAD file. From there we can evaluate the deviations between the nominal and actual piece. The comparison can also be made between two samples, one of them serving as a reference. Deviations are displayed using a color code that highlights the differences between the parts.

Get Started

If you’ve got questions on material thickness and gap width, get in touch with one of our industrial CT scanning experts. At Diverse Dimensions we use a state-of-the-art, highly flexible X-ray CT scan system with six linear motorized axes allowing for optimized magnification for a variety of sample types and scanning configurations. We can set up a time to discuss the benefits of CT scanning and how non-destructive testing NDT can help you.