Accurate to 20 microns (,020mm/.008”), we provide trustworthy dimensional data that helps you detect issues early in the manufacturing process. Improve product quality and reduce rework by catching nonconformities before they impact production.

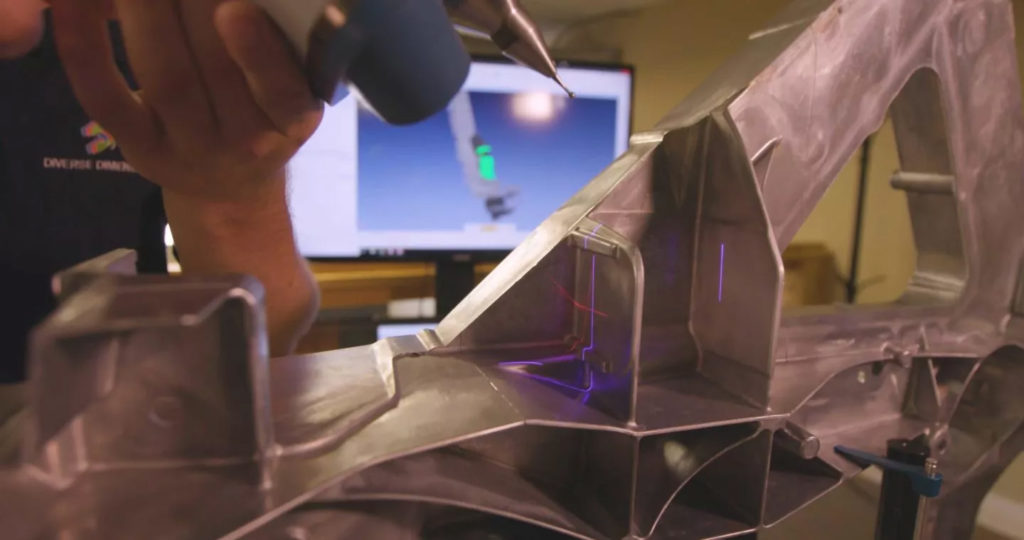

Our Portable Inspection and 3D Laser Scanning Services

No part is too big and no distance too far – our equipment is portable, so we can come to you. We can probe and laser scan your manufactured part, assembly, or tooling and then provide insights that are unattainable with traditional measurement equipment. We can compare complex geometries to existing CAD, compare one part to another and create CAD models all from the same dataset.

Portable Inspection and 3D Laser Scanning Applications

We have experience in every industry, and with a wide variety of applications. Trust your project to our experienced metrology professionals.

Dimensional Analysis & Inspection

Identify nonconformities that affect part, item, or assembly performance before they become costly downstream issues.

First Article Inspection (FAI)

Ensure conformance with design specifications and quality standards.

Geometric Dimensioning & Tolerance (GD&T) Analysis

Test flatness, parallelism, perpendicularity, cylindricity, concentricity, maximum material conditions, and position tolerance in coordinate systems.

Part to CAD Comparison

Overlay 3D scan data with your CAD model to detect deviations, validate form and fit, and accelerate iterative design processes.

Part-to-Part Comparison

Compare parts from different molds, suppliers, or production runs to evaluate consistency, detect tooling wear, or qualify new processes.

Primary Benefits of Portable Inspection & Laser Scanning

Experience Portable, Thorough,

& Accurate Inspection Services

Whether you choose in-house or on-site, let our large team of committed metrologists put their extensive experience to work for you. No matter your issue or concern, we’re dedicated to finding metrology solutions and uncovering ways to save time, money, and make product or production improvements.